Conoce SGAR

NUESTRA EMPRESA

SGAR – CSI son dos empresas formadas por profesionales de la automatización y con una clara orientación hacia la calidad, el servicio y buscando la satisfacción de nuestros clientes.

SGAR fue fundada en 2001 inicialmente estaba formada por un equipo reducido de técnicos con amplia experiencia. Con el tiempo SGAR ha evolucionado y crecido en alcance de actividades y volumen de trabajo y para poder dar un buen servicio, se han ido formando diferentes equipos de trabajo para dar cabida a esta evolución.

Nuestro objetivo es ser referentes en Europa, y estar siempre actualizados en las últimas tecnologías para garantizar la mayor competitividad en este mercado.

En 2008 se formó la empresa CSI que consta de un equipo de personas con prestaciones orientadas a un colectivo de clientes de un ámbito más cercano, y de esta manera prestar un servicio más accesible en función de las demandas de nuestros clientes.

%

Gestión de proyectos

Trabajos de planificación, captación, dinamización, organización y Canada Goose Langford Parka administración de recursos, con el fin de culminar todo el trabajo requerido para desarrollar un proyecto y cumplir con el alcance, dentro de límites de tiempo, y costo definidos.

%

Automatización industrial

Servicios de desarrollo, realización y implantación de proyectos para automatización industrial.

%

OLP - Virtual Comissioning

A partir de modelos mecánicos en 3D generamos la cinemática necesaria para simular de forma precisa procesos OFF-line. A partir de aquí, se puede realizar desde estudios de accesibilidad hasta la generación del programa código para cargar en la controladora del robot.

Nuestros

Partners

Año de fundación

Nº de proyectos en 2015

Nº de técnicos propios

Datos Generales

Somos una empresa formada por profesionales de la ingeniería y de la automatización con una clara orientación hacia la CALIDAD, el SERVICIO y las necesidades del CLIENTE.

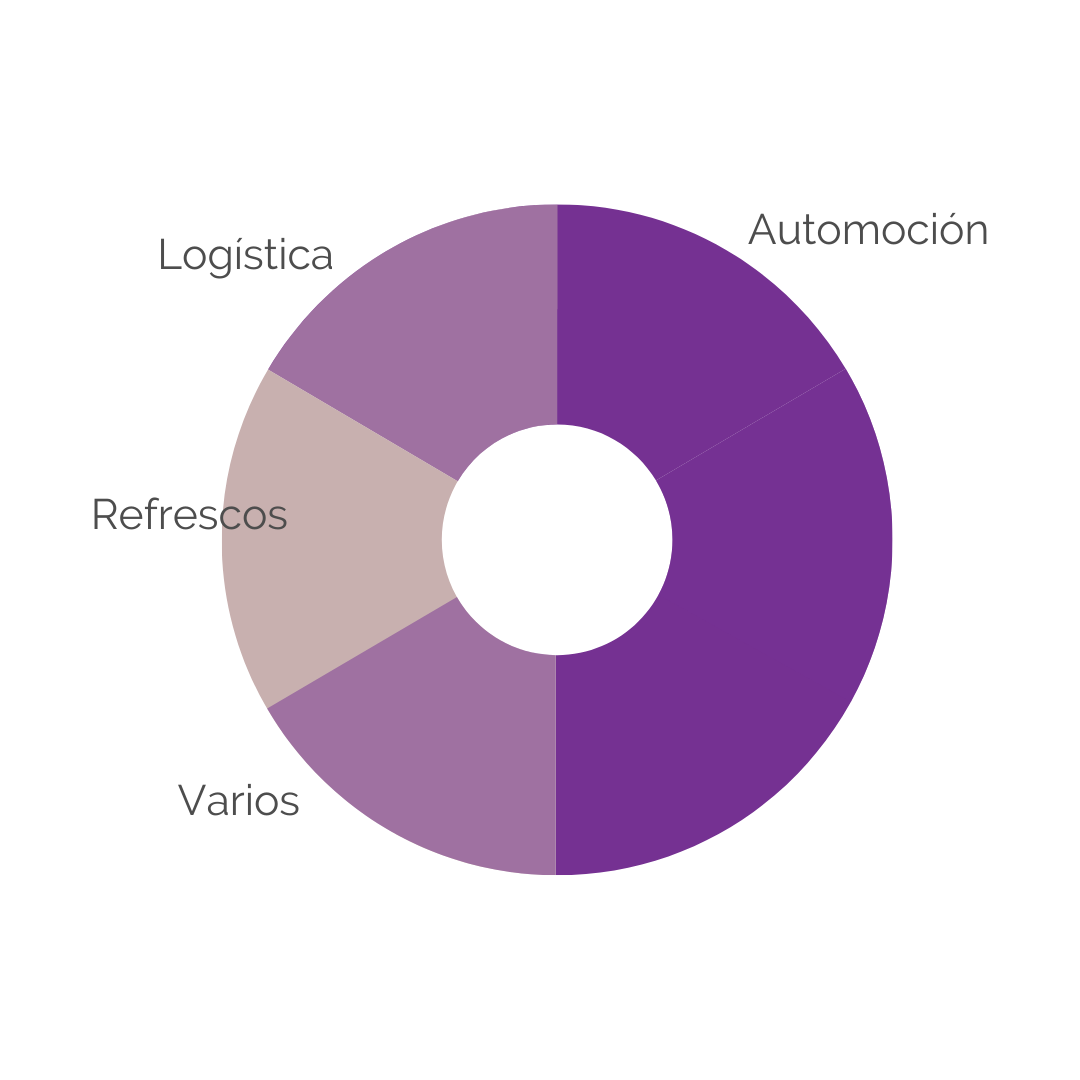

Clientes

Amb el suport de: